The Selection of Mud Recovery Systems

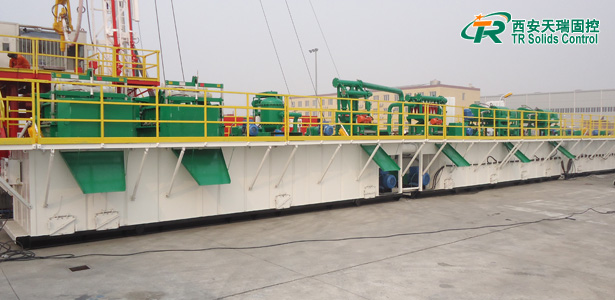

The mud recovery system is mainly used to handle the harmful solid phases in the mud. The treated slurry can be reused. TR Solids Control is a manufacturer of mud recovery systems.

Precautions for selecting mud recovery system:

1. Select the precision of mud treatment based on the type of drilling.

2. The processing capacity of the selected mud recovery system should be the same as the drilling requirements.

3. Select the mud recovery system scheme for the drilling site space.

4. Choose a mud recovery system manufacturer with certification.

TR Solids Control has been deeply engaged in the solid control industry for over 10 years. TR products are compatible with all scenarios including trenchless HDD, geothermal drilling, oilfield drilling, and pile foundation engineering.

The advantages of TR mud recovery system:

1. Leading technology, industry benchmark for separation efficiency.

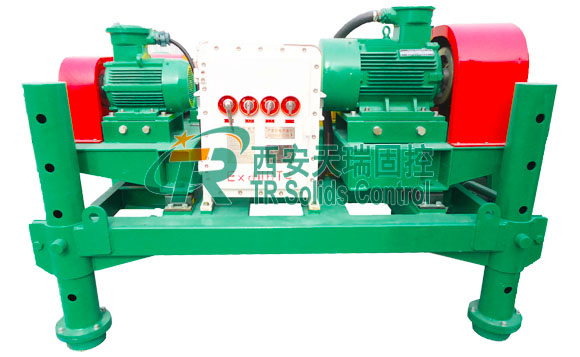

Integrated shale shaker, desander and desilter into one. The cyclone flow channel is optimally designed, and the Angle of the screen box is adjustable. The separation accuracy is precise to 2-5μm. The sand particle removal rate of the mud recovery system can reach up to 98% at most.

2. The mud recovery system is available in a complete range of models. Meet various mud recycling requirements.

3. Full-process service, worry-free after-sales.

We offer free customized solutions based on customer needs. The production process of the mud recovery system is subject to customer supervision. Provide free technical training on the use of mud recovery systems for customers.

Tianrui Solid Control has over 10 years of technological accumulation. Industry-leading separation efficiency and comprehensive service guarantee; It not only meets the current construction needs, but also reduces costs and increases efficiency for long-term operation.

TR mud recovery system is exported to many countries in the European Union and the Middle East. TR has already become one of the world’s well-known manufacturers of mud recycling. Whether it is trenchless, geothermal or oilfield projects, Tianrui Solid Control is the best choice in terms of performance and cost-effectiveness.

The function of the Drilling Mud Recovery System

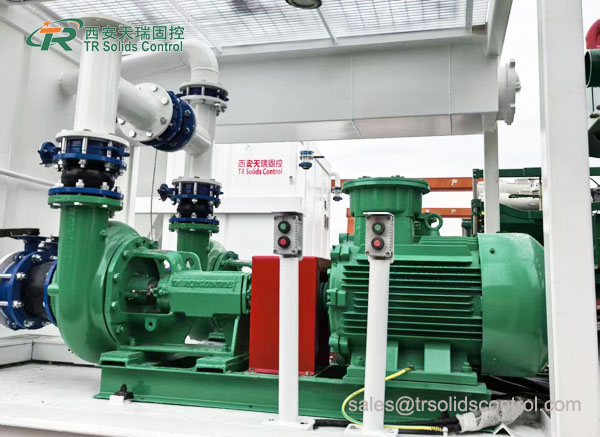

The drilling mud recovery system is mainly used to separate solid particles from the mud generated during drilling or construction, achieving purification and recycling of the mud, thereby reducing construction costs and meeting environmental protection requirements. Drilling Mud recovery systems are widely used in trenchless engineering and oil drilling. Its core objective is to treat the slurry through multiple solid control devices (such as shale shaker, cyclones, and centrifuges). Remove impurities such as drill cuttings from it to restore the reusable performance of the mud.

The drilling mud recovery system not only enhances operational efficiency but also complies with increasingly strict global environmental protection regulations. For instance, it has become a standard device in on-site applications such as horizontal directional crossing (HDD) and coalbed methane extraction.

TR Solids Control has passed multiple international certifications including API, ISO and CE. The mud recovery system meets the export requirements.

Main functions and workflow of drilling mud recovery system

1. Large drill cuttings are initially screened out through shale shaker, and then fine particles are further removed by desander, desilter or centrifuge.

2. The cleaned base liquid can be remixed by adding new mud materials to meet the standards for reuse.

Resource recycling.

3. The separated clear water can be used for dust suppression, concrete curing or re-preparation of slurry.

The solids control system and solids control equipment produced are exported to many countries in the Middle East and Southeast Asia.