Tag Archives: mud recovery system

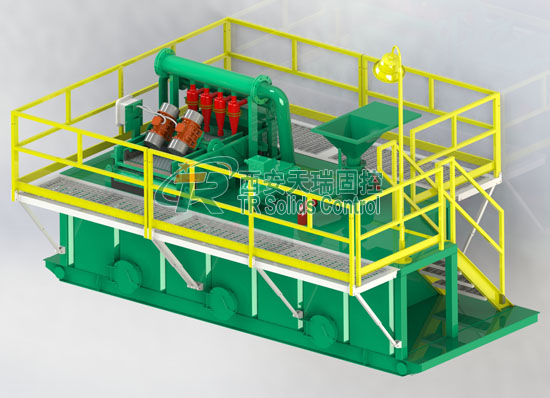

High Capacity TBM Slurry Separation Plant

Tunneling solids control is one of the three existing methods of tunnel construction, this method is applicable to tunnel excavation in the construction of the soft soil layer or the formation of water content is high. TR TBM slurry separation plant is of modular system construction. It is designed for the treatment of all kinds of slurry used in common construction techniques.

TBM slurry separation plant, tunnel solids control system, shield mud recovery system

This system is beneficial to control the mud performance, enhance the quality and efficiency of the hole, fully support and ensure smooth operation of the tunneling equipment, meanwhile improve the recycling of mud. It not only saves construction costs, but also lowers the mud emissions and reduces environmental pollution. This kind of mud recycling system is economical, efficient and friendly to environment.

Main Technical Data of TR TBM Slurry Separation Unit

|

Single Unit Capacity |

|||

|

Max.Slurry Capacity |

120m3/h | Total Installed Power | 82.8kW |

|

Purification Desanding Separation Size |

d50=0.074mm | Max.Water Content of Screen Underflow |

30% |

|

Coarse Shale Shaker |

TRDGS900 | Power |

2.2KW X 2 |

| TRDG700 | Power |

1.94KW X 2 |

|

|

Desander Pump Flow |

120m3/h | Motor Power |

37kW |

|

Desilter Pump Flow |

120m3/h | Motor Power |

37kW |

|

Desander Hydrocyclone |

12” | Hydrocyclone Qty |

2 pcs |

|

Desilter Hydrocyclone |

4” | Hydrocyclone Qty |

8 pcs |

| Dimension(L*W*H) | 6.5m×2.5m×7m | Total Weight |

10t(appr.) |

| Solid Content Less Than | 30% | Max.Proportion of Slurry Treatment Less Than |

1.25g/cm³(±0.1) |

TR tunnel boring mud system, TBM mud separation system, TR shield mud system

Are you looking for a suitable system to recycle your tunnel mud? TR Solids Control can help. We specialize in designing and manufacturing high performance mud recycling system and solids control equipment for your needs. Shale shaker, shaker screen, desander & desilter, mud agitator, jet mud mixer, centrifugal pump are our hot products. We are here ready to support you!

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Mud Recovery System in Microtunneling Construction

Microtunneling (MT) is a method of installing pipes below the ground, by jacking the pipe behind a remotely-controlled, steerable, guided, articulated microtunnel boring machine (MTBM). The MTBM, which is connected to and followed by the pipe being installed, ensures that the soils being excavated are fully controlled with the rate of advancement of the boring machine at all times.

Mud recovery system in microtunneling construction, drilling fluids solids control system

Mud recovery system is supporting facilities that TR develops for the environmental protection of drilling mud treatment during microtunneling construction. By using shale shaker, desander, desilter or mud cleaner, shear pump and other solids control equipment, we achieve the purpose of purification and reuse of drilling waste sludge, which promotes the rapid and efficient progress of microtunneling construction. Through this system, waste mud can be recycled and used. This saves the cost for users, improves the economic benefit of customers, protects the drilling rig, at the same time protects the surrounding environment from pollution.

Mud cleaning system, shield mud recycling system, shale shaker, mud desander

TR Solids Control is a professional manufacturer to supply mud treatment solutions in microtunneling construction. Besides this, we also supply mud recovery system in oil & gas drilling, horizontal directional drilling, bored piling and drilling waste management. We are sincerely welcome you to visit our factory and check our facilities.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Oil-Based Drilling Waste Management

In order to implement and follow environment requirements, TR Solids Control developed a set of drilling waste management independently. This system makes the mud pit disappear completely, and can realize harmless treatment during drilling. TR team has made our own contribution to environmental protection.

Oil-based drilling waste management, liquids solids separation, DWM manufacturer

Our oil-based drilling waste management is mainly divided into waste drying collection unit, liquid phase separation unit. As for disposal of waste mud, we need to add gel breaker processing unit.

1.Thermal Washing Facility

In this process, thermal washing facility will be injected into a certain percentage of hot water. Then we transport oil-base mud drilling cuttings to the thermal washing facility with screw conveyor. The oil from the drilling cuttings off in the stirring of mixer continuously. At this time, the thermal washing facility completes this process.

2. Waste Drying Collection Unit

In this process, we transport the drilling cuttings treated by solids control equipment to high-frequency vertical cutting dryer with screw conveyor. After dryer treating, large particles of drilling cuttings in solids control equipment are separated and stripped.

(Solid-phase water content can be controlled within 10%) Drilling waste cuttings are collected and transported timely to the lower tank for caching and pre-treatment.

3. Liquid Phase Separation Unit

In this process, we transport the mud filtered by vertical cutting dryer to variable-frequency high speed centrifuge through industrial pump(screw pump) of the centrifuge for deep separation. After treatment, solid phase separated is collected, and liquid phase will be transported to drilling fluids circulating system for recovery through sand pump.

Mud circulating system, oil sludge treatment system, solids control unit

As a main and well-known manufacturer of solids control equipment and drilling waste management, TR Solids Control always put customers’ requirement in the first place. If you have any inquiry about shale shaker, shaker screen, mud cleaner, desilter, desander, mud agitator, jet mud mixer, decanter centrifuge, centrifugal pump, shear pump etc, welcome to contact us freely. TR will provide our best price and service to you.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Merry Christmas and Happy New Year to All of TR Clients

The Christmas and New Year holiday is coming near once again. TR Solids Control team would like to extend our warm wishes for the upcoming holiday season. Wish all of you and your family a Merry Christmas and a prosperous New Year. May your New Year be filled with special moment, warmth, peace and happiness, the joy of covered ones near, and wishing you all the joys of Christmas and a year of happiness.

TR Solids Control factory, mud solids control equipment supplier, mud recovery system manufacturer

Many thanks for your contiguous supports and trusts to TR Solids Control in the past years. We wish both of our business snowballing in the coming years. Thinking back the past one year 2017, TR received many new orders from old and new clients. We served every client with our good quality product and good service, and received many positive feedback from clients. This gives us much motive to do better in the coming 2018. Customer’s satisfaction is always the highest pursuit of TR Solids Control. We will insist our company policy to provide more solutions for clients.

TR Solids Control wishes to client, Merry Christmas and Happy New Year

One you have any inquiry about solid control equipment or mud recovery system in the following days, hope you could feel free to contact with us. TR Solids Control will quote our competitive price and short delivery to you. Hope everyone succeed in year 2018!

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

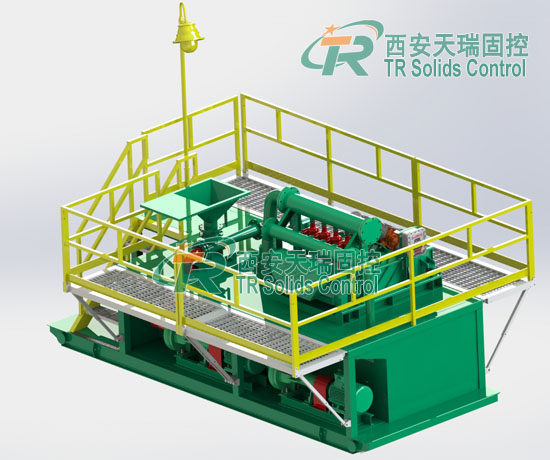

Mini Mud Treatment System Shipped to South Africa

At the end of October, TR Solids Control completed a batch of mini mud treatment system package for South Africa clients after days of production, assembly and commissioning. This mud system will be applied in their local HDD trenchless field. The total capacity is up to 100m3/h.

Mud treatment system for HDD trenchless, customized mud package system

The mini mud treatment system consists of 4 main modules which are mud tank module, mud agitator module, jet mud mixer module, shear pump module.The design capacity is 100 m3/h and can meet the needs of mud treatment on HDD construction site. At present, this kind of mini mud recovery system designed and manufactured by TR Solids Control has characteristics of compact design, easy transportation, quick delivery time, high efficiency and low construction cost. It could reduce mud usage and environment pollution, so that it is widely used not only in the field of No-dig drilling site, but also in oil & gas drilling, bored pile construction, tunnelling construction, and get a lot of recognition by our customers.

Mud treatment system delivery, mud cleaning equipment, drilling fluids solid control equipment

TR Mud Treatment System and Solid Control Equipment are widely used for oil gas drilling, horizontal direction drilling, water well drilling, mining, and construction mud treatment. We have the one stop turn-key solutions for you from shale shaker, shaker screen, desander, desilter to decanter centrifuge. TR not only provide individual equipment but also we provide customized package system.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

HDD Mud Recycling System

HDD mud recycling system is designed for trenchless technology requirement. HDD mud recycling system is used for purify the underground mud in the horizontal directional drilling process. Using the shale shaker and mud cleaner to separate the bigger size solids out. Then using the jet mud mixer to add required chemicals and stir evenly to make sure the mud can reused. Use the mud pump to pump the mixed well mud to drilling system. TR Solids Control’s mud recycling system has good advantage of high treating capacity, convenient delivery and good quality. It is widely used in HDD trenchless filed, construction piling and CSM exploration.

TRHDD-1000 mud recovery system parameter

| Model | TRHDD-200 | Model | TRHDD-500 | TRHDD-1000 |

| Capacity | 200GPM (50m3 /h) | Capacity | 500GPM (120m3 /h) | 1000GPM (240m3 /h) |

| Desilter | TRZS752S | Shale Shaker | TRZS703/TRZS585 | TRZS703/TRZS585 |

| Total area of upper screen | 0.875m2 | Total screen area | 2.7m2 | 2X2.7m2 |

| Total area of lower screen | 1.35m2 | Model of high-efficiency cleaner | TRQJ250X1S-100X8N | TRQJ250X2S-100X12N |

| Cyclone Specs | 4″ | Desander cyclone | 10″×1pcs | 10″×2pc |

| Cyclone Qty | 4pcs | Desilter cyclone | 4″×8pcs | 4″×12pcs |

| Model of feed pump | TRSB4X3-12J | Total area of underflow screen | 1.35m2 | 2.12m2 |

| Model of mixing pump | TRSB4X3-11J | Feed pump of cleaner | TRSB6X5-11J 2pcs | TRSB8X6-11J 2pcs |

| Model ofmixing hopper | TRSLH100 | Model of mixing pump | TRSB6X5-12J | TRSB8X6-12J |

| Total power | 44kW | Model of mixing hopper | TRSLH150-35(37KW) | TRSLH150-35(45KW) |

| Total volume | 5m3 | Model of agitator | TRJBQ7.5 | TRJBQ7.5 |

| Total volume | 4000×2360×2940mm | Total power | 130kW | 184kW |

| Total weight | 5500kg | Total volume | 15m3 | 30m3 |

| Total volume | 10000×2360×4228mm | 12100×2630×4438mm | ||

| Total weight | 17000kg | 20000kg |

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:13186019265

Call:13186019265

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com

Web:www.chinasolidscontrol.com

Drilling fluids recovery system is designed for Trenchless project

Drilling fluids recovery system is specialized designed for Trenchless project.Its working principle is to simply separate the waste from drilling fluids, not all of the solids waste, it is just to separate the unnecessary parts. Like bentonite and some drilling fluids additives are solid state, while what we need is the tiny size, so it is much important that to measure the particle size, and the measure unit is always for μm. The system can separate 100μm and bigger particle from a 100μm screen.

It is important to realize that the correct mixer of bentonite for mud recovery system is sub-micron grade size, it means the bentonite is not easy to be separated from fluids. The size of the digged soil can range from 1000 microns to submicron according to the different formation drilling.

Clay is smaller than sand soil, while the rock cutting bigger than both. The smaller the particle size is, the more difficult the separation will be. In Trenchless industry, it is not economic to separate less than 20μm particle mostly, so the submicron bentonite cannot be separated from the common fluids recovery system. Our goal is to separate the waste, and make the fluids recycling during drilling.

So the fluids recovery system and the spare parts are all designed for the same goal.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:13186019265

Call:13186019265

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com

Web:www.chinasolidscontrol.com

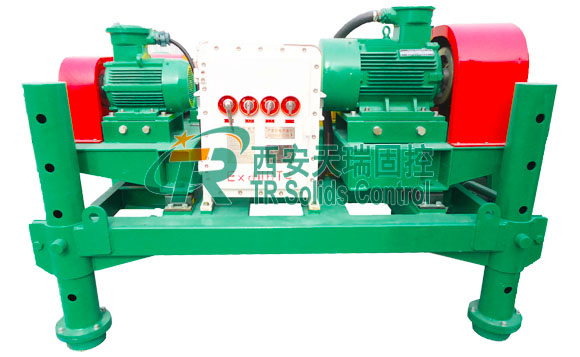

New Balanced Elliptical Motion Shale Shakers for Mud Recovery System

Based on the oilfield test sand compared with other shaker types,balanced elliptical motion shale shakers can consistently provide gentle rolling motion,better solids removal and fluid circulation,less screen wear.

Balanced Elliptical Motion Shale Shakers is designed for various solid conditions. With balanced elliptical shaking track, such shale shake is most advanced with features of quick disposal, high capacity, good screening efficiency with prolonged screen life, and easy to install and maintain.

Balanced elliptical motion shale shakers,drilling mud shale shakers

Balanced Elliptical Motion Shale Shakers for Mud Recovery System

Balanced Elliptical motion Shakers cuttings discharge more convenient, the capacity of balanced elliptical shale shakers will increase by 25%-30% comparing with the linear motion shale shaker in the same specification which has been tested many times.

The balanced elliptical movement of balanced elliptical shale shakers strengthens the dehydration of shaker screen, and it makes the drilling cuttings drier, which reduce the drilling cost.

Balanced Elliptical Motion Shaker supplier,drilling fluid shale shakers

We are an china Mud Recovery System Manufacturer.Our factory approval the API,Elliptical Motion Shale Shaker have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid solids control manufacturers and balanced Elliptical Motion Shale Shakers supplier.We will provide the high quality drilling fluid Shale Shakers and best service.Your best mud drilling fluid solids control start from TR solids control.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:13186019379

Call:13186019379

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com

Web:www.chinasolidscontrol.com