Tag Archives: Factory price decanter centrifuge

Main Structure of TR Decanter Centrifuge

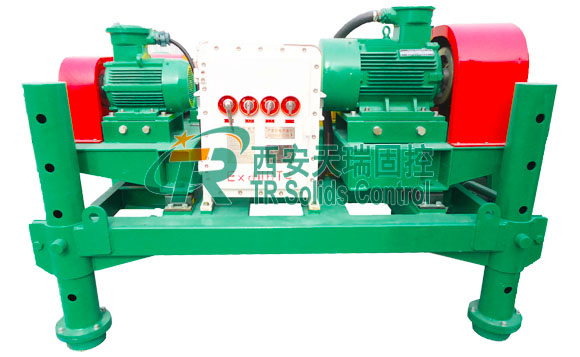

Decanter centrifuge is the fourth solid control facility in processing drilling fluid. Main unit of Centrifuge is made up of bowl, conveyor(screw propeller), big end bearing plate, small end bearing plate, differential, main drive motor, auxiliary drive motor, hydraulic coupling, bearing seat, rotating body shield, drive shield, transmission belt, control box, and the base, etc. Bowl and conveyor(screw propeller) are core components of decanter centrifuge. Solid phase separation of drilling fluid is proceed here.

Oil sludge centrifuge, drilling fluid centrifuge for sale

Precision and quality of parts manufacturing directly affect centrifuge’s solid phase separation effect and service life. Bowl is made of a cylindrical cylinder and a conical cylinder. Cylindrical cylinder for solid phase subsidence area, meanwhile conical cylinder for dehydration area. There are eight overflow openings in the big end plate of the bowl. And adjustable overflow plate on overflow hole, which adjusts depth of the liquid level inside cylinder by changing the different positions of the baffle, so as to realize different separation effect.

Solid control mud centrifuge, API standard mud centrifuge

On the small end circle of the bowl, there are two rows of staggered 28 tungsten carbide nozzles, which separates solid phased particles within the bowl under effect of the centrifuge discharged here. Among inner surface of cylinder rods can form a solid phase layer due to the effect of rod. This stops the circular motion of solid layer, thus protecting bowl inner wall from wearing. Bowl cover is composed of box cover and lower box, connected with hinges. Lower box is divided into two separate chambers with baffle, by the big end side of chamber to collect liquids phase from overflow opening. We welcome your inquiry of our decanter centrifuge!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Decanter Centrifuge for Drilling Waste Management

Decanter centrifuge is the fourth solid control equipment in handling drilling fluid. It’s used to separate suspension liquid by adopting principle of centrifugal sedimentation. It mainly separates 2-7μm solid particles in drilling fluid. Nowadays, TR mud centrifuge is widely also commonly used in industry of drilling waste management.

Oilfield mud centrifuge for sale, factory price mud centrifuge, good quality mud centrifuge

TR Solids Control is a lead and professional manufacturer of decanter centrifuge. TR decanter centrifuge is high in recovery rate, also effective in solids control and remarkable in the reduction of cost spent on drilling mud resupplying and management. Below is the main technical data of our decanter centrifuge.

| Model | TRLW600B-1 | TRLW450N-1 | TRLW450N-2 | TRLW355N-1 | TRLW355NB-1 |

| Bowl Diameter | 600mm | 450mm | 450mm | 355mm | 355mm |

| Bowl Length | 1500mm | 1000mm | 1250mm | 1250mm | 1250mm |

| Bowl Speed | 2200r/min | 2200r/min | 3200r/min | 3200r/min | 0~3200r/min |

| Treatment Capacity | 90㎥/h | 50㎥/h | 40㎥/h | 40㎥/h | |

| G-Force | 815 | 815 | 2035 | 2035 | 0~2035 |

| Separation point | 5~7μm | 5~7μm | 2~5μm | 2~7μm | |

| Separation point | 40r/min | 40r/min | 30r/min | 30r/min | 0-30r/min |

| Gear Box Ration | 35:1 | 57:1 | |||

| Main Drive Motor | 55kw | 30kw | 37kw | 30kw | 37kw |

| Back Drive Motor | 15kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

| EX Standard | ExdIIBt4 / IECEX / A-TEX | ||||

| Wright | 4800kg | 2700kg | 3200kg | 2900kg | 3200kg |

| Dimension | 2900×1900×1750mm | 2600×1860×1750mm | 2600×1860×1750mm | 2600×1620×1750mm | 2600×1620×1750mm |

TRLW mud decanter centrifuge in field, good price mud centrifuge

Above all, TR Decanter Centrifuge can meet with different requirements of mud treatment under various drilling conditions. As a famous manufacturer of decanter centrifuge manufacturer in China, our centrifuge has good price also high quality. Furthermore, we have other solid control equipment like shale shaker, mud cleaner, mud agitator, centrifugal pump, shear pump, jet mud mixer, also mud gas separator etc.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com