Tag Archives: Drilling waste management

OBM Drilling Waste Management Shipment

As the professional manufacturer in China, TR Solid Control could design and manufacture various model Drilling Waste Management or or Cutting Dryer System according to the customers requirement. On May.10th, one new batch of oil based drilling waste management was shipped to our old customer. Currently this system is widely used in Chinese domestic market for compact structure and high efficiency.

Oil based drilling waste management was shipped to our old customer.

This system is composed of TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank, centrifuge supply pump and other auxiliary accessories. Processing capacity of our dryer could reach up to 30-50 T/h with basket diameter 930mm. Rotary speed is 900r/min. Bowl diameter of our TRLW355N-1 centrifuge is 350mm, and bowl length is 1250mm. Processing capacity is 40m3/h. TR drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

Our drilling waste management is with compact structure and high efficiency.

TR Solids Control is one of the most famous international brand for Mud Solids Control System & Drilling Waste Management in China. We have one stop service for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. For more information about our drilling waste management, please visit: www.trsolidscontrol.com/drilling-management-system.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com

Working Process of Drilling Waste Management

Drilling waste management is a common name for drilling cuttings treatment, also known as drilling fluid non-grounding. It refers to adopt mud non-grounding equipment for screening out the waste and cuttings from drilling fluid. This reduces land use and environmental pollution. TR Solids Control is a professional manufacturer of both WBM and OBM drilling waste management for 11 years.

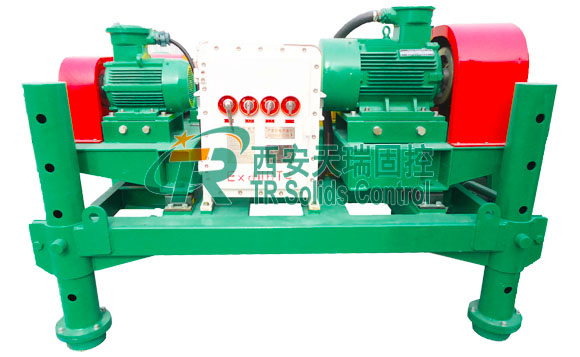

Drilling waste management for oilfield, vertical cutting dryer

Working process of our drilling waste management is described as follows:

The mud from drilling rig enters shale shaker and mud cleaner through elevated manifolds, and drill cuttings discharged after treatment are transported to vertical cutting dryer for treatment through screw conveyor. The solids treated by the dryer are removed through waste residue, then the recovered drilling mud enters drilling fluid mud tank . Centrifuge supply pump or screw pump extracts the fine solid particles. The recovered mud is supplied to the centrifuge for processing, solid part is removed through the solid discharge port, and the processed drilling fluid returns to mud system through the clean mud.

TR Solids Control is a manufacturer of drilling waste management.

TR Solids Control is one of the most famous International Brand for Mud Solids Control System & Drilling Waste Management in China. We have the one stop for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. Our products are certified by API, Europe CE, and Russia TP and TC. The explosion proof standard can be IEC Ex, or ATEX certified for developed countries for Zone 1 and Zone II application. If any inquiry, welcome to contact with us freely.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com