Tag Archives: Drilling fluids mud centrifuge

Features of TR Decanter Centrifuge

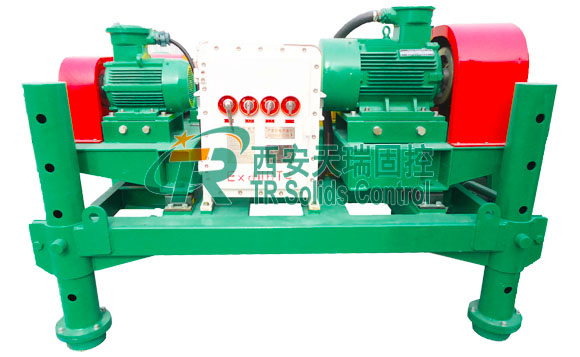

TRLW series decanter centrifuge adopts solid-liquid density difference to form two-phase separation under the function of centrifugal force. It’s mainly for the recovery of barite, removing fine solids and reducing the solids content of drilling fluid, also controlling the density and viscosity of the drilling fluid. Finally this ensures the performance of drilling fluid, also has an rather important role in rapid drilling.

Drilling fluids decanter centrifuge, oil sludge centrifuge, mud centrifuge for sale

Features of TR Decanter Centrifuge:

- Straight and cone section of the drum made from 2205 duplex stainless steel material, because we adopt centrifugal casting process;

- Remaining components of the drum assembly made from SS316L;

- Screw carrier adopts YG6 wear-resistant alloy sheet protection. With long life, also easy maintenance and replacement;

- Diversion port of screw pusher and slag-drip opening of the drum almost protected by replaceable wear-resistant alloy sleeve. While this delays the service life and maintenance cycle.

- Drum assembly protected with demountable support frame in transit, preventing damage to bearing;

- Using imported even more SKF and NSK bearings to improve equipment stability and bearing life;

- Frequency control facilitates customers to adjust speed at any time. Also this meets different working conditions;

- Schneider or Siemens electrical components. While current overload & mechanical limit switch dual protections.

Oilfield drilling mud centrifuge, high efficiency decanter centrifuge, API standard mud centrifuge

Above all, TRLW series Decanter centrifuge are almost used to process unweighted and weighted, water-based and oil-based drilling fluids (muds). Furthermore, TR Solids Control is a professional manufacturer of decanter centrifuge in China. Welcome you to visit our factory at any time!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com