Tag Archives: Drilling fluid desander

Mud Desander System Delivered to Drilling Site

TR mud desander system is widely used in mini trenchless projects like horizontal directional drilling, tunnelling, city bored piling industry etc. After one-month manufacturing, TRZX-60/45 mud desander system is ready for delivering to our client’s bored piling desanding plant. Yesterday the clients came to our factory for inspection, and they were very satisfied with our equipment.

TRZX-60/45 mud desander system is ready for delivery.

TRZX-60/45 mud desander system is composed of one 8” cyclone desander, one TRZS753 double-deck liner shale shaker, one TRSB 4×3-12 centrifugal pump, electrical control system, mud-storage tank, connecting pipeline, and cyclone holder. This system can improve the efficiency of urban construction, reduce labor time and labor cost, and save water. It’s the first choice in present bored pile mud recycling system.

TR mud desander system will be used in city bored piling.

TR Solids control is the main and professional mud recycling system manufacturer in China. We are an exporter of mud desander system. Our factory approvals the API certification. We will provide the high-quality mud recycling system and best service to you. In addition, we supply other solid control equipment like shale shaker, mud cleaner, decanter centrifuge, jet mud mixer, desilter, vertical cutting dryer, mud gas separator, mud gun, flare ignition devicem mud agitator and so on. Welcome your inquiry and consulting!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com

Desanding Plant Delivered to Malaysia Piling Field

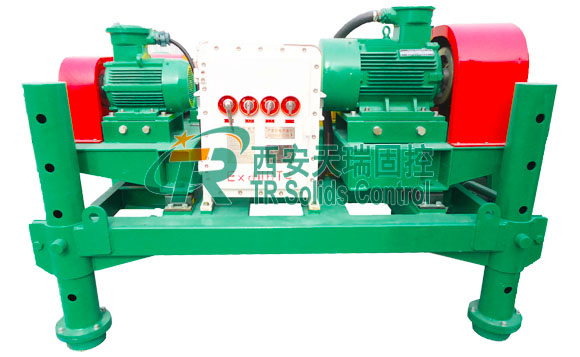

After tense production for half a month, TR Solids Control just finished the fabrication of desanding plant for an Malaysia piling company. Now this system are under delivery testing procedure, and later will be delivered to client.

Bored pile desanding plant, mud recovery system for piling construction

The whole system includes one set double layers shale shaker, one set centrifugal pump, one set mini mud tank, and other auxiliary equipment desilter. It combines two different kinds of mud cleaning methods vibration screening and cyclone separation together to form a closed-circuit recycling purification system for mud treatment. The processing ability is strong, 15μm-44μm particles in the slurry can be quickly disposed of, which makes use cost reduced, and the mud treated by circulating system can be recycled and used. This system greatly reduces the environmental pollution, and it is one of the necessary equipment in piling construction.

Desanding plant delivery, good performance piling mud cleaning system

TR Solids Control is well-known as manufacturer of solid control equipment and mud recovery system. Our equipment are widely used in many industries for solids and liquid separation like drilling fluids recycling, dredging slurry separation, piling mud recovery, tunnel slurry cleaning etc. If you need separation solutions, welcome to contact with TR.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Desander is The Second Class Equipment in Solid Control System

Drilling fluid desander is a kind of hydrocyclone desander composed of hydrocyclone and shale shaker. It is the second class solid control equipment to treat drilling fluids, mainly used for separating solid particles with size 47 ~ 76μm.

Drilling fluid desander, mud desander, desander for oil & gas drilling, top quality desander

Our TRCS series desander overcomes shortcomings of the original sand removal process. The hydrocyclone of desander is provided with a rotating component, and its cylindrical wall is with a separation window. The upper cylinder wall of the rotating member, a set of tapered grooves and liquid inlet pipe constitute drilling fluid lifting component. Impeller of desander is set at the interior of the component, and sand regulator controls the amount of sand. The drilling fluid enters the rotating component from the inlet pipe, after centrifugal rotation of the blade, the liquid rises to the separation window when the sand is separated from the drilling fluid, the sand is discharged into the sanding cone through the separation window. The separated drilling fluid enters the lifting component, and drilling fluid is discharged into the drilling tank by the drain of the conical groove. The sand in the cone is discharged from the sand outlet controlled by the sand regulator device and the separation is completed.

Drilling desander for HDD, oilfield mud desander, TRCS series desander, excellent desander

Technical data of TRCS series desander:

| Model | TRCS200-1S/2S | TRCS250-1S/2S | TRCS250-3S | TRCS300-1S/2S |

| Capacity | 60m3/120m3/h | 100m3/200m3/h | 300m3/h | 120m3/240m3/h |

| Cyclone Specs | 8” | 10” | 10” | 12” |

| Cyclone Qty | 1nos/2nos | 1nos/2nos | 3nos | 1nos/2nos |

| Working Pressure | 0.25-0.4Mpa | |||

| Inlet Size | DN125mm | DN150mm | DN150mm | DN150mm |

| Outlet Size | DN150mm | DN200mm | DN200mm | DN200mm |

| Separation Point | 45μm -75μm | |||

| Bottom Shaker | TRTS60 | TRTS60 | TRZS752 | TRZS752 |

| Dimension | 1510*1160*2000mm | 1510*1360*2250mm | 1835*1230*1810mm | 1835*1230*1810mm |

| Weight | 570kg/620kg | 670kg/760kg | 1300kg | 1380kg |

| Remark | All desilter could be customized without bottom shaker. | |||

Mud desander in drilling site, hydrocyclone desander, solid control mud desander

TR Solids Control is your one-stop solution for solid control equipment. We specialize in the design and manufacture of high performance shale shaker, mud cleaner, mud agitator, mud gun, jet mud mixer, centrifugal pump, submersible slurry pump etc. and mud mixing system for oil & gas drilling, HDD trenchless, shield & bored pile. You best choice starts from TR Solids Control!

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Piling Desander Used in Bored Pile & TBM

As an increasing need for protecting the environment, people have high equipment requirements in bored pile and TBM industry. Piling desander is developed under in such a situation. As environmental high-tech product, it’s for recycling and reusing the mud in bored pile & TBM. It can improve efficiency of city construction, reduce labor time and cost, save water resource. As a first class mud recycling manufacturer, TR Solids Control designs and develops our own pilling desander. It has been tested in drilling site of domestic and foreign construction company, and gets high appraise. It’s the first choice in present bored and TBM mud recycling.

Piling desander, drilling desander, bored pile & TBM desander, top quality desander

Technical data of TR piling desander:

| Model | TRZX-50/25 | TRZX-100/50 | TRZX-200/50 |

| Liquids Capacity | ≤50m³/h | ≤100m³/h | ≤200m³/h |

| Solids Capacity | ≤26T/h | ≤50m³/h | ≤50m³/h |

| Separation Point | 25μm | 50μm | 50μm |

| Shale Shaker | TRZS753 | TRZS753 | TRZS705 |

| Screen Area | Top: 700×1250 | Top: 700×1250 | Top: 750×900×2 |

| Bottom: 750×900×2 | Bottom: 750×900×2 | Bottom: 700×1250×3 | |

| Vibration Power | 1.0kw×2 | 1.0kw×2 | 1.5KW×2 |

| Centrifugal Pump Configuration | TRSB4×3-12(15KW) | TRSB5×4-13(30KW) | TRSB6×5-13J(45KW) |

| Hydrocyclones Configuration | DN200×1 | DN250×1 | DN250×2 |

| Tank Size | 2100×1500×2600mm | 3050×2000×1200mm | 3600×2100×1200mm |

| Dimension | 2200×1600×2600mm | 3120×2200×2380mm | 3700×2200×25400mm |

Piling desander in drilling site, mud recycling system, Bored pile & TBM system, mud desander

TR Solids Control is the first class manufacturer in mud recycling. We mainly provide piling desander, piling desilter, shale shaker, shaker screen, HDD recycling unit in bored pile & TBM industry.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com