Tag Archives: Decanter centrifuge

Decanter Centrifuge & Vertical Cutting Dryer for Drilling Company

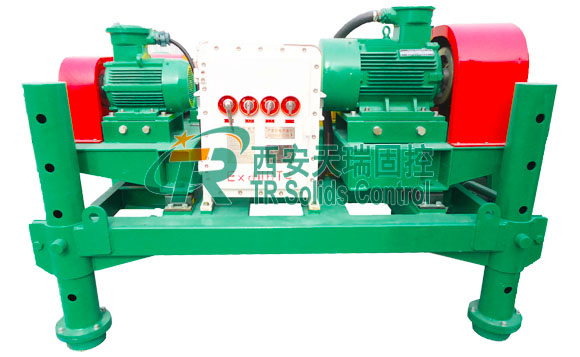

TR Solids Control has rich experience in designing and manufacturing decanter centrifuge and vertical cutting dryer. At this week, we shipped new solid control equipment to our domestic drilling field. It includes 1pc TRLW450N-2 decanter centrifuge and 1pc TRCD930C vertical cutting dryer. The final installation and commissioning work has been completed and is expected to be delivered to our old customer in the short term.

Decanter centrifuge and vertical cutting dryer are ready for delivery.

Decanter centrifuge is the fourth solid control equipment in handling drilling fluid. According to different rotary speed, it can be divided into middle speed centrifuge, high speed centrifuge and high speed frequency centrifuge. Our model TRLW450N-2 belongs to high speed type and has long bowl length 1250mm, bowl diameter is 450mm. Its rotary speed could arrive 3200r/min. TRLW series decanter centrifuge delivers high fluid-recovery rates and efficient solids control to significantly reduce the costs of makeup fluids and disposal.

Vertical cutting dryer and decanter centrifuge will be shipped to drilling company.

Vertical Cutting Dryer is one of the popular products for OBM and WBM. It is a kind of drying machine for handling mud in oilfield. The capacity of our model TRCD930C vertical cutting dryer is 30-50 T/h. Maximum basket diameter is 930mm, and rotary speed is 900 r/min. It has two electric motors, main motor power is 55kw, and oil pump power is 0.55kw. In addition, we have variable-frequency models available to customers’ requirements. TRCD series vertical cutting dryer can recover the oil cuttings in the composition, oil content of cuttings after treatment is generally less than 3%.

TR exported directly or sold with supporting drillers to more than 30 countries and regions in the world such as Russia, United States, Australia, Latin America and the Middle East etc. Making sure to support first-class solid control equipment with developing “Made in China” as our own tasks. Holding forward-looking to each task, every drawing has technicity to direct, every process has worker to follow up and every product has QC to check on. To provide customers with a full set of solid control equipment solutions effectively is our company’s goal.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com

Main Structure of TR Decanter Centrifuge

Decanter centrifuge is the fourth solid control facility in processing drilling fluid. Main unit of Centrifuge is made up of bowl, conveyor(screw propeller), big end bearing plate, small end bearing plate, differential, main drive motor, auxiliary drive motor, hydraulic coupling, bearing seat, rotating body shield, drive shield, transmission belt, control box, and the base, etc. Bowl and conveyor(screw propeller) are core components of decanter centrifuge. Solid phase separation of drilling fluid is proceed here.

Oil sludge centrifuge, drilling fluid centrifuge for sale

Precision and quality of parts manufacturing directly affect centrifuge’s solid phase separation effect and service life. Bowl is made of a cylindrical cylinder and a conical cylinder. Cylindrical cylinder for solid phase subsidence area, meanwhile conical cylinder for dehydration area. There are eight overflow openings in the big end plate of the bowl. And adjustable overflow plate on overflow hole, which adjusts depth of the liquid level inside cylinder by changing the different positions of the baffle, so as to realize different separation effect.

Solid control mud centrifuge, API standard mud centrifuge

On the small end circle of the bowl, there are two rows of staggered 28 tungsten carbide nozzles, which separates solid phased particles within the bowl under effect of the centrifuge discharged here. Among inner surface of cylinder rods can form a solid phase layer due to the effect of rod. This stops the circular motion of solid layer, thus protecting bowl inner wall from wearing. Bowl cover is composed of box cover and lower box, connected with hinges. Lower box is divided into two separate chambers with baffle, by the big end side of chamber to collect liquids phase from overflow opening. We welcome your inquiry of our decanter centrifuge!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Features of TR Decanter Centrifuge

TRLW series decanter centrifuge adopts solid-liquid density difference to form two-phase separation under the function of centrifugal force. It’s mainly for the recovery of barite, removing fine solids and reducing the solids content of drilling fluid, also controlling the density and viscosity of the drilling fluid. Finally this ensures the performance of drilling fluid, also has an rather important role in rapid drilling.

Drilling fluids decanter centrifuge, oil sludge centrifuge, mud centrifuge for sale

Features of TR Decanter Centrifuge:

- Straight and cone section of the drum made from 2205 duplex stainless steel material, because we adopt centrifugal casting process;

- Remaining components of the drum assembly made from SS316L;

- Screw carrier adopts YG6 wear-resistant alloy sheet protection. With long life, also easy maintenance and replacement;

- Diversion port of screw pusher and slag-drip opening of the drum almost protected by replaceable wear-resistant alloy sleeve. While this delays the service life and maintenance cycle.

- Drum assembly protected with demountable support frame in transit, preventing damage to bearing;

- Using imported even more SKF and NSK bearings to improve equipment stability and bearing life;

- Frequency control facilitates customers to adjust speed at any time. Also this meets different working conditions;

- Schneider or Siemens electrical components. While current overload & mechanical limit switch dual protections.

Oilfield drilling mud centrifuge, high efficiency decanter centrifuge, API standard mud centrifuge

Above all, TRLW series Decanter centrifuge are almost used to process unweighted and weighted, water-based and oil-based drilling fluids (muds). Furthermore, TR Solids Control is a professional manufacturer of decanter centrifuge in China. Welcome you to visit our factory at any time!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

New Batch Solids Control Equipment Sent to Oil & Gas Drilling Site

TR Solids Control is known as solids control equipment manufacturer in China. One of the fields where our solution can be applied is oil and gas drilling. Recently, our previous customer had an urgent requirement about new batch of solids control equipment for supporting their oil & gas drilling project. This project is located in the desert of Chinese Inner Mongolia, where have rich oil and gas storage but harsh environment. After half a month manufacturing, these equipment are finished and delivered to the site urgently.

Solids control equipment, drilling desander, liquid gas separator, decanter centrifuge, oil and gas drilling solids control

This order is made up of 1 set TRLW450×1000 decanter centrifuge, 2 sets TRZS585 shale shakers, 1 set TRCS250×2S drilling desander, 1 set TRZYQ1000 liquid gas separator, 1set TRYPD-20/3 flare ignition device and related blowout pipelines. One of our technicians was sent to deliver and help them to install these equipment. After arriving drilling site, customer was satisfied with our equipment and service. They choose to establish long-term cooperation with us. It is the biggest inspiration for all of TR people.

Drilling fluid desander, shale shaker, decanter centrifuge, liquid gas separator, top quality solids control equipment

TR solids control equipment and mud recycling system keep your project and cost under control. As a matured member of this field, we can provide a wide variety of linear and balanced elliptical motion shakers, mud cleaners, desanders, desilters, degasser,and decanter centrifuges, or some related facilities such as mud tank, water tank, mud gun etc.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com